Cold chain "Quality from the beginning to consumption".

Günter Dorn - Veröffentlicht am 30 January 2023

Before a food product is consumed, it usually travels a long distance. On this journey, it is important for all food to maintain the cold chain. For some foods, maintaining certain temperatures is even more important, as the risk of quality deterioration is particularly high. Find out which foods are affected, what the regulations are for the cold chain and what the possible consequences of an interrupted cold chain can be in this blog post.

What is a cold chain?

A cold chain for food is divided into 4 stages:

- Production

- Storage

- Transport

- Delivery

A continuous refrigeration system is particularly important for transport from the producer to the wholesaler and finally to the consumer. In order to guarantee the quality of the food during transport, there are special containers and vehicles with different cooling chambers, which are adapted to the respective requirements of certain foodstuffs.

What legal regulations apply to the cold chain of food products?

Legal regulations have been established to minimize the dangers of an interrupted cold chain.

They provide for the prevention of:

- Higher temperatures

- Food in contact with water

- Easy spread of microorganisms through liquid

- Connection with melted ice

That is why the HACCP concept was developed. The concept is a binding quality assurance system for food, which is internationally valid. It includes, among other things, the holistic recording and monitoring of temperatures in the manufacturing process, through transport to storage of the food. In this way, compliance with the legally specified refrigeration temperatures is to be demonstrated. In addition, the concept prescribes certain requirements for in-house control systems.

What are the consequences of an interrupted cold chain?

The top priority of a cold chain is that it is not interrupted. This means that the respective temperatures should remain the same throughout. As soon as the temperatures deviate too much from the legal requirements, the quality and shelf life of the food can no longer be guaranteed. Meat and fish are particularly susceptible to the production of bacteria. Temperature differences of as little as +/- 3 °C are not permissible and can have a massive impact on food quality. The spread of germs, bacteria and salmonella, can be hazardous to human health. For this reason, legal guidelines have been imposed to prevent hazards.

In addition to endangering people, an interrupted cold chain can lead to major damage to the company's image.

Example: Melted ice in cold chains

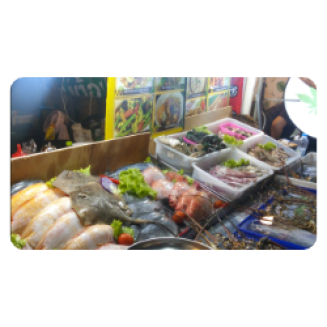

One risk is hidden in melted ice. In melted ice, microbes and parasites can spread more quickly. In countries with high outside temperatures, the risk is greatly increased. This is because a rapid multiplication of microorganisms can quickly become an uncontrollable danger. It is therefore essential to avoid contact between food and melted ice. The melted water must be able to drain off without coming into contact with the product. Here it is important to check regularly and ensure that the drainage channels are not dirty and clogged. This is because if the liquid builds up in the gutters, the temperature in the surrounding area will rise very quickly. If the fish and seafood are removed from the support surface, it must be defrosted, cleaned and disinfected at the end of the opening time.

Also, the production of fresh ice must be done with clean water and properly cover the base to cool the food, because the cooling temperature must reach the whole product.

In Thailand, for example, the fish and seafood are often presented in front of the supermarket, market or restaurant. The risk due to the high outside temperature here is very high and an optimal environment for the spread of various microorganisms.

How fresh fish really is can be recognized by various characteristics. Please read the brochure from the BfR: https://mobil.bfr.bund.de/cm/343/wie-frisch-ist-der-fisch-kennzeichen-von-frischen-fischen.pdf.

When implementing the legal requirements, the respective individual situation of the business must always be considered. I will be happy to support you in this. I am also happy to be your personal contact for the optimization of your existing measures. Contact me to identify your savings potential!

List of sources:

https://www.chromonorm.de/ratgeber/kuehlkette/

https://www.bmel.de/DE/themen/verbraucherschutz/lebensmittel-hygiene/rechtsgrundlagen-lebensmittelhygiene.html

https://www.q-s.de/faq-de/was-ist-unter-dem-begriff-kuehlkette-zu-verstehen.html

https://static-int.testo.com/media/7a/c1/9c0edc25ee1c/Tipps-und-Tricks-fr-khlkette

Weitere Use-Cases

„Ich bin da, wo auch immer Sie mich benötigen.“

Ich stehe Ihnen mit umfassenden branchenspezifischen Kenntnissen im Bereich der Reinigungsprozesse zur Seite.

-

Conscious sustainability in professional use02 June 2023

-

Avoiding listeria infection: where and how?20 April 2023

-

Cross-contamination: This is how it can be prevented in the online trade of unpackaged goods!13 March 2023

-

Cold chain "Quality from the beginning to consumption".30 January 2023

-

Food defense in indoor bakery16 January 2023

-

Mandatory reuse 202305 January 2023

© JD5 - Günter Dorn

Crafted with ❤ by Werwolf Media.

English (United Kingdom)

English (United Kingdom)  Deutsch (Deutschland)

Deutsch (Deutschland)